Advantage

This makes our Polyester Silos unique

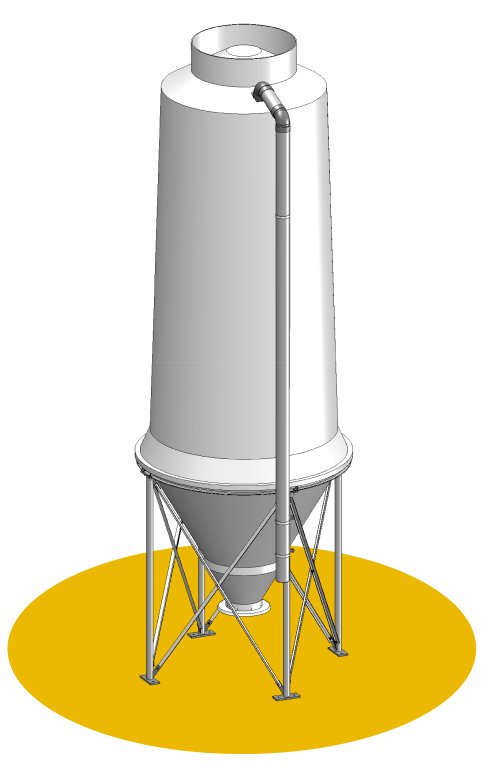

GRP silos embedded in a plant concept offer strong advantages over conventional silos made of stainless steel, sheet metal, aluminum or concrete, especially for industrial applications. We therefore offer our polyester silos in sizes of up to 1500 m³ designed especially for industrial companies.

POLYESTERSILOS: The best way to store products for industrial use

Better than stainless steel, sheet metal, aluminum and concrete silos

Longer service life

Thanks to their excellent resistance to environmental influences and chemicals, GRP silos have a longer service life compared to aluminum and stainless steel silos.

Low maintenance

GRP silos require little maintenance, such as painting after a few years or anti-corrosion treatments.

Smooth inner walls

The smooth inner walls of GRP silos reduce the buildup of materials and make cleaning easier, compared to corner silo types.

Flexible sizes

GRP silos can be adapted to different space and room requirements and therefore offer greater design flexibility.

Lowest condensation

GRP silos have very low thermal conductivity, which protects the contents from temperature fluctuations and enables energy savings - better than any other silo material.

Corrosion resistance

GRP silos are highly corrosion resistant compared to aluminum and stainless steel or concrete silos, which significantly extends their service life.

Resistance to chemicals

GRP silos are resistant to a wide range of chemical substances, which expands their application possibilities.

Environmental friendliness

Compared to all other silo types, GRP silos generate less environmental impact during their production and disposal and therefore have a lower ecological impact.

Lightweight

GRP silos are lighter than concrete silos, which makes transportation and installation easier and saves costs.

.png)

"A silo is not just a silo. Just as a car is not the same as another car.

Not every product can be stored in every silo. It is important that the bulk density and the flow properties are taken into account in the technical design of the silo. Often silo suppliers use silos also for heavy stored goods, although their silos are designed only for a bulk density of 600 kg/cbm. This is dangerous and also not permitted! Make sure that your silo is permissible for the bulk weight!"

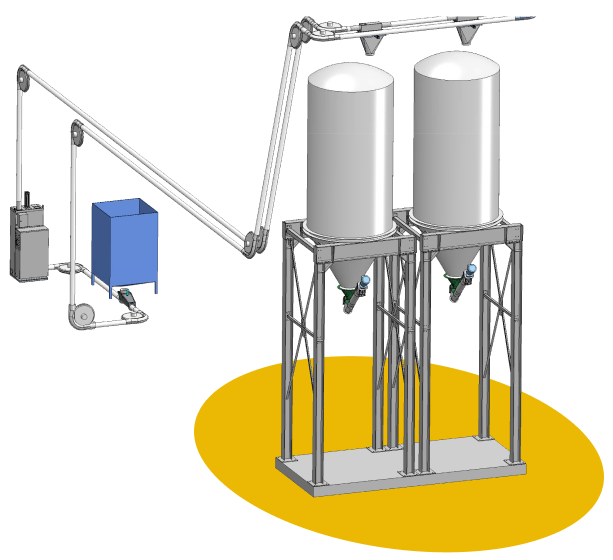

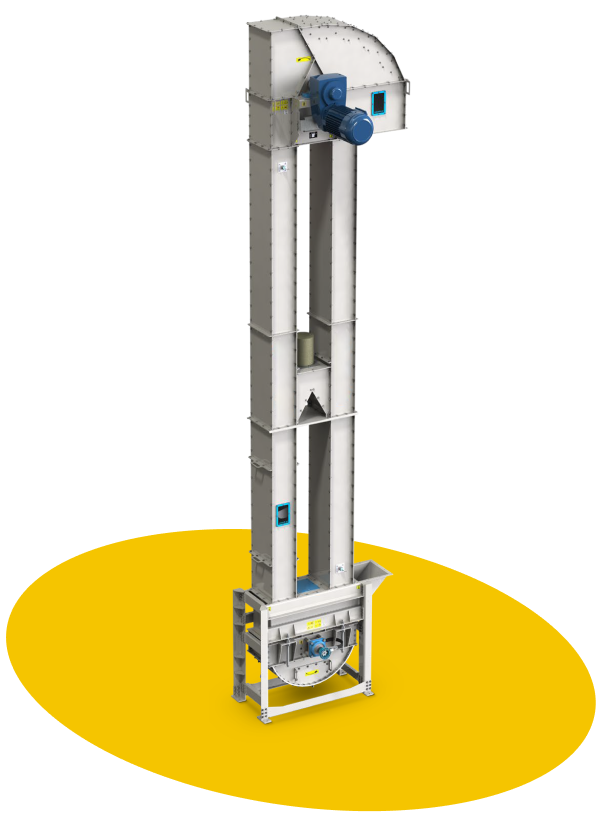

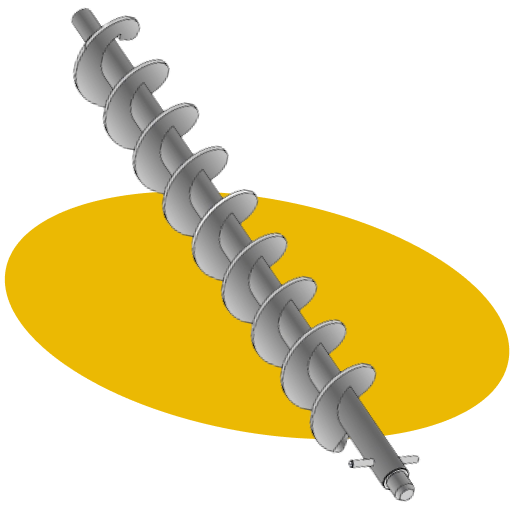

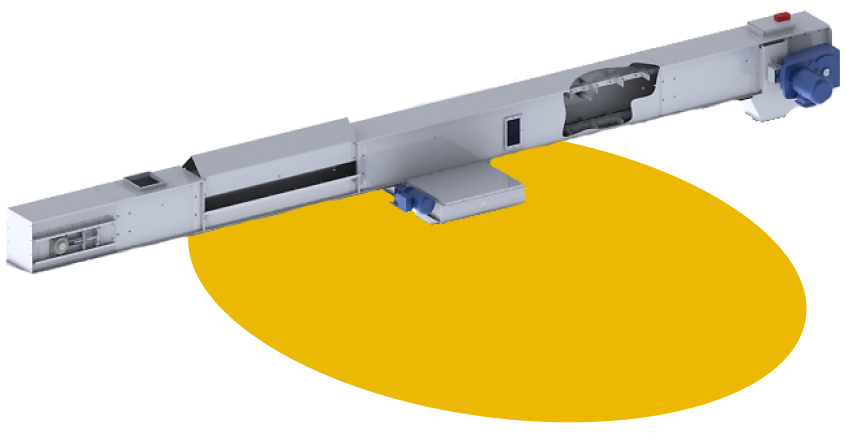

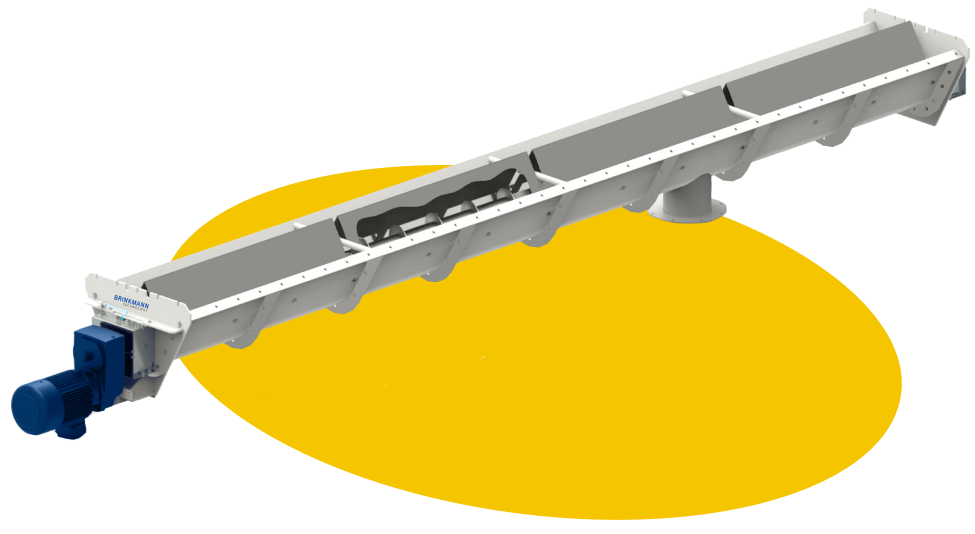

Frank Brinkmann Managing DirectorDischarge and filling equipment

Unique: Only with us you can also get attractive leasing offers for your silos on request!

"Safety is a high priority for us. With our access ladders, rest platforms, railings and walkways, we ensure compliance with accident prevention regulations (UVV).

We will be happy to conduct a hazard assessment of your stored goods with you and discuss necessary measures for discharge assistance, prevention of a dust explosion and prevention of damage due to overpressure during pneumatic filling."

Frank Brinkmann

Managing Director