Trough Chain Conveyors

whose robust construction will inspire you

to listed corporations

Facts

The Trough Chain Conveyor at a glance

Trough chain conveyors transport bulk materials (e.g. sand, coal, grain), often heavy bulk materials, in a closed conveyor trough with the aid of a chain strand on which the goods to be transported are placed.

get personal advice3-100m

conveying

0-1500 t/h

capacity

0 / 45

degree of conveyance

Application

This is why you need Trough Chain Conveyor

You need

Horizontal, long conveying paths with high conveying capacities

Durability in demanding environments due to robust materials

Wide range of applications in various industries

Conveying of food products possible

Application

Application cases

Heavy haulage

Trough chain conveyors can be used to transport heavy materials such as ore, gravel, coal and other bulk materials. They are capable of carrying large loads and can thus facilitate material transport in demanding environments.

Transporting abrasive materials

Trough chain conveyors are capable of transporting abrasive materials such as sand, gravel and other bulk materials. This makes them a useful transport solution for the construction industry.

Nearly all industries

Trough chain conveyors can be used to process bulk materials in a variety of industries such as grain or feed industry, breweries, chemical and pharmaceutical industry and waste management.

Advantages

Advantages of the Trough Chain Conveyor

High performance

Trough chain conveyors are capable of transporting heavy materials with high weight and volume.

Robust and Durable

Trough chain conveyors are made of sturdy materials and can withstand demanding environments.

Wide application

Trough chain conveyors can be used in various industries, including mining, heavy industry, food and beverage, and waste management.

Long conveying distance

Trough chain conveyors are suitable for simple but long conveying distance up to 100m.

Components

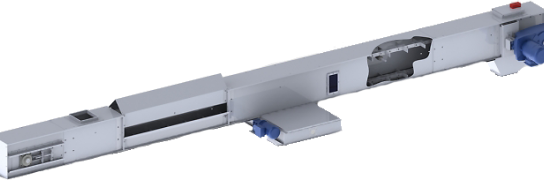

The main components

of the Trough Chain Conveyor

Drive unit

Robust and high-quality drive station in various power levels, which moves the chain and is thus the heart of the trough chain conveyor.

Deflection station

Robust and high-quality deflection station in which the chain is tensioned.

Conveyor shaft with chain

Robust and high-quality conveyor shafts for the transport of free-flowing bulk materials.

Technical specifications

Technical specifications 0 º Inclination

|

BT40-N0 |

BT60-N0 |

BT80-N0 |

BT100-N0 |

BT150-N0 |

BT200-N0 |

BT300-N0 |

BT400-N0 |

BT600-N0 |

|

|---|---|---|---|---|---|---|---|---|---|

|

Capacity (t/h)

|

40 |

60 |

80 |

100 |

150 |

200 |

300 |

400 |

600 |

|

Trough diameter (mm) |

231 |

261 |

261 |

327 |

405 |

468 |

518 |

618 |

962 |

|

kW for e.g. 10 m conveying distance |

1,5 |

2,0 |

2,6 |

3,1 |

4,5 |

5,9 |

8,6 |

11,4 |

16,9 |

|

kW for e.g. 20 m conveying distance |

2,2 |

3,1 |

4,0 |

5,0 |

7,3 |

9,6 |

14,2 |

18,8 |

27,9 |

Technical specifications

Technical specifications 45 º Inclination

|

BT60-N45 |

BT80-N45 |

BT100-N45 |

BT150-N45 |

|

|---|---|---|---|---|

|

Capacity (t/h)

|

60 |

80 |

100 |

150 |

|

Trough diameter (mm) |

261 |

261 |

327 |

405 |

|

kW for e.g. 10 m conveying distance |

2,0 |

2,6 |

3,1 |

4,5 |

|

kW for e.g. 20 m conveying distance |

3,1 |

4,0 |

5,0 |

7,3 |