Bucket Elevators

Efficient vertical conveying that inspires you

to listed corporations

Facts

The Bucket Elevator at a glance

Our bucket elevators are the optimal solution for vertical conveying of bulk materials in many different industries. Thanks to their high conveying capacity of up to 200 t/h and the ability to convey up to 70 m high, they offer a flexible and reliable solution for a wide range of applications.

get personal advice7

models

3-70m

height

20-200 t/h

capacity

Advantages

Advantages of the Bucket Elevator

Effective conveying

Our bucket elevators offer an effective and reliable solution for conveying bulk materials of all kinds. They can transport bulk materials with a conveying capacity of up to 200 t/h, making them suitable for demanding applications.

High reliability

Our bucket elevators are robust and durable, offering high reliability even under the most challenging conditions.

Flexibility

We offer a wide range of bucket elevators in various designs to meet the different requirements of our customers.

Low maintenance

Our bucket elevators are easy to assemble and maintain, and offer high reliability and durability. As a result, maintenance costs are minimal.

Space-saving

Our bucket elevators require little space, making them suitable for confined spaces.

Desired finish

We offer custom painting, hot-dip galvanizing or stainless steel finish to meet our customers' requirements.

Optional monitoring

Speed monitoring and bearing temperature monitoring are optionally available to enable precise control and monitoring of operation.

ATEX design

We offer pressure shock resistant bucket elevators for use in hazardous areas, designed according to the present ATEX zone and the expected maximum explosion overpressure.

Application

Application cases

Agriculture

Bucket elevators are ideal for vertical conveying of bulk materials in agriculture. For example, they can be used for conveying grain, barley, wheat, corn, legumes, and farinaceous components. In addition, they can also be used for conveying artificial fertilizers and other agricultural products.

Feed industry

In the feed industry, bucket elevators are ideal for vertical conveying of feeds such as grain, pellets and other bulk materials.

Breweries

Bucket elevators are an important component in breweries for vertical conveying of malt, barley, and other bulk materials. They can also be used for vertical conveying of waste products such as husks and spent grains.

Chemical industry

Bucket elevators are ideal for vertical conveying of bulk materials in the chemical industry. For example, they can be used for conveying granules, powders, and other bulk materials.

Building materials industry

In the building materials industry, bucket elevators are often used for vertical conveying of sand, gravel and other bulk materials.

Recycling industry

In the recycling industry, bucket elevators can be used, for example, for the vertical conveying of plastic granules, metal chips, and other bulk materials.

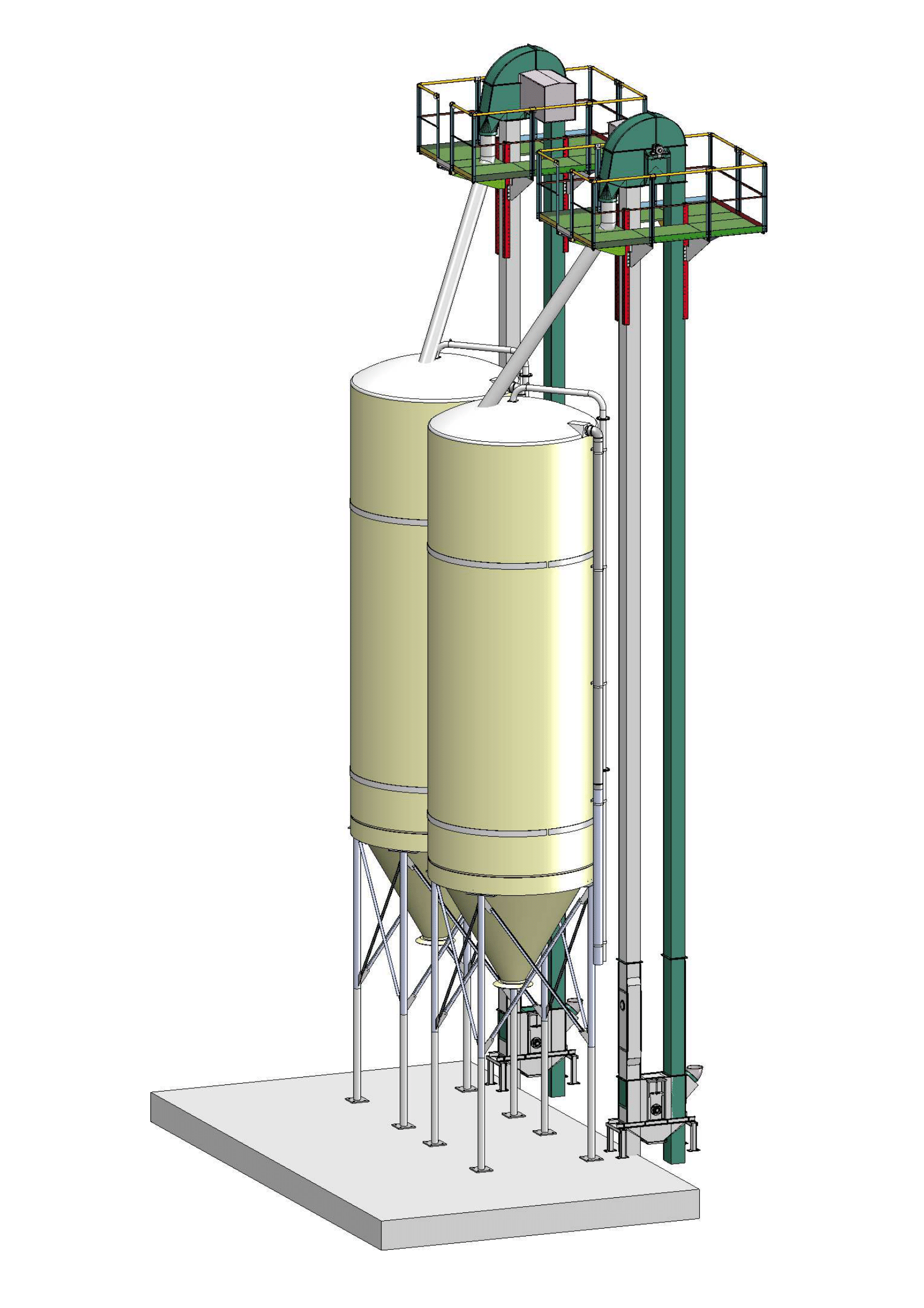

Plant concept

Integration into your storage concept

We integrate our bucket elevators perfectly into your existing plant concept, e.g. to enable vertical conveying of your products into storage silos. We not only provide you with our conveyor technology, but also supply other plant technology such as storage technology, e.g. GRP silos.

Contact & Learn moreComponents

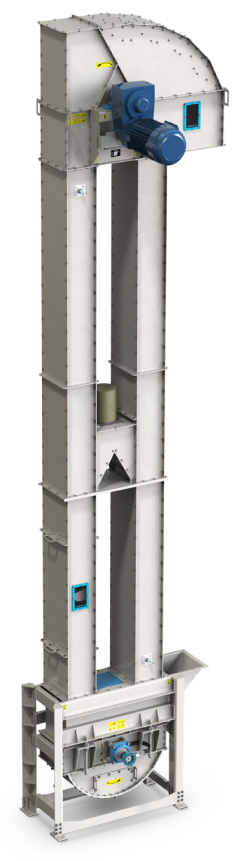

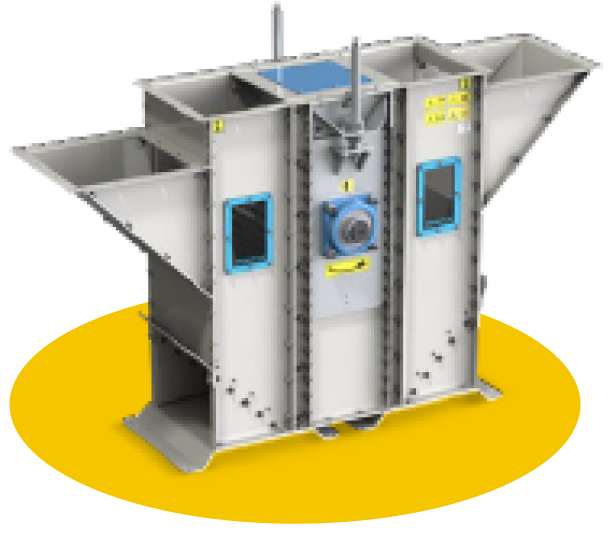

The main components

of the Bucket Elevator

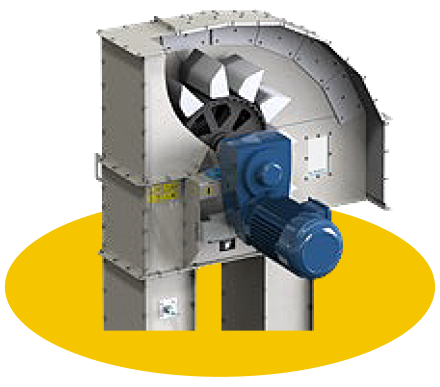

Head

Robust and high-quality drive station in various power levels that moves the chain and is thus the heart of the bucket elevator.

Pulley

The pulley is used to guide the elevator belt.

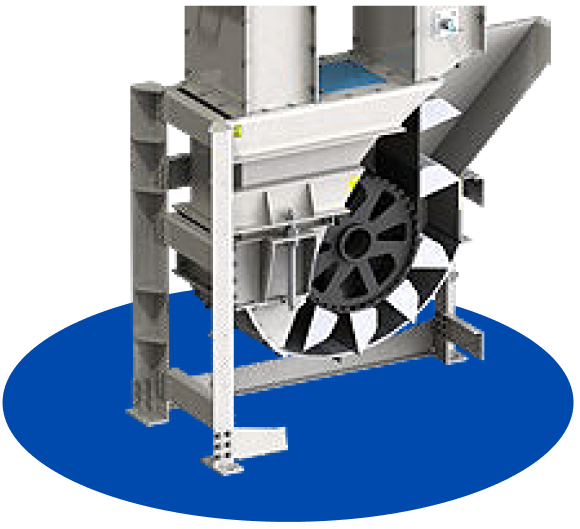

Foot

The foot serves as the inlet and designates the place where the pulley is located.

Technical specifications

Technical specifications

|

BT-B130 |

BT-B180 |

BT-B280 |

BT-B370 |

BT-B450 |

BT-B740 |

BT-B900 |

|

|---|---|---|---|---|---|---|---|

|

Capacity (t/h) |

20-40 |

40-80 |

80-160 |

160-300 |

230-340 |

340-500 |

500-650 |

|

Belt width(mm) |

150 |

200 |

300 |

400 |

500 |

800 |

1000 |

|

kW for e.g. 10 m conveying distanc |

2,56 |

5,12 |

10,24 |

19,5 |

28,6 |

42,7 |

61,3 |

|

kW for e.g. 20 m conveying distance |

3,66 |

7,33 |

14,65 |

28,0 |

41,0 |

61,4 |

88,5 |