Feed production

Fully automatic production

of quality feed

We plan and build for you an individual plant for the production of quality feed specifically tailored to your needs. No matter whether you want to produce the feed on your farm and use it for your own animals, or whether you produce feed for sale - we are at your side as a reliable partner.

Customized feed

per animal species

Use of own raw materials

Full confidence in the ingredients

Independence & cost savings

Increase your success with our modern, robust and innovative technology, underpinned by our decades of experience.

You can produce customized feed quality for different animal species under full control, using your own raw materials. The feed is thus always fresh and you have full confidence in the feed quality, recipes and ingredients.

up to several

1000 €cost saving per day

mixing time

conveying technology

Why 80% of all farmers can benefit from fully automated forage production without even knowing it.

Thanks to our grinding and mixing equipment, you are independent of the compound feed industry and can improve the usability of feed components.

The uniform feed mixtures ensure optimal feed intake for your animals.

In addition, our plants are more cost-effective than ready-made feed and reduce the workload through automatic control.

Advantages

This makes our

grinding and mixing plants unique

Our grinding and mixing plants are a worthwhile investment for 80 % of all farmers who want to benefit from cost-efficient and high-quality feed production.

Optimize your feed production with our state-of-the-art equipment and increase the performance and health of your animals!

Individual

The possibility of individual feed mix formulations have been proven to lead to e.g. higher milk yields.

Cost reduction & less effort

More cost-effective and better than ready-made feeds with reduced effort due to automatic system control

High quality

Higher feed quality and freshness improving the performance of your animals. Full confidence in quality, recipe & ingredients due to own hand.

Independence

Independence from the compound feed industry by using your own farm products and data-driven decisions for your farm control.

Production of high quality feed for various species of animals

Pigs

Sheeps

Goat

Chicken

Fish

Cattle & Cows

Horses

Turkeys

many more!

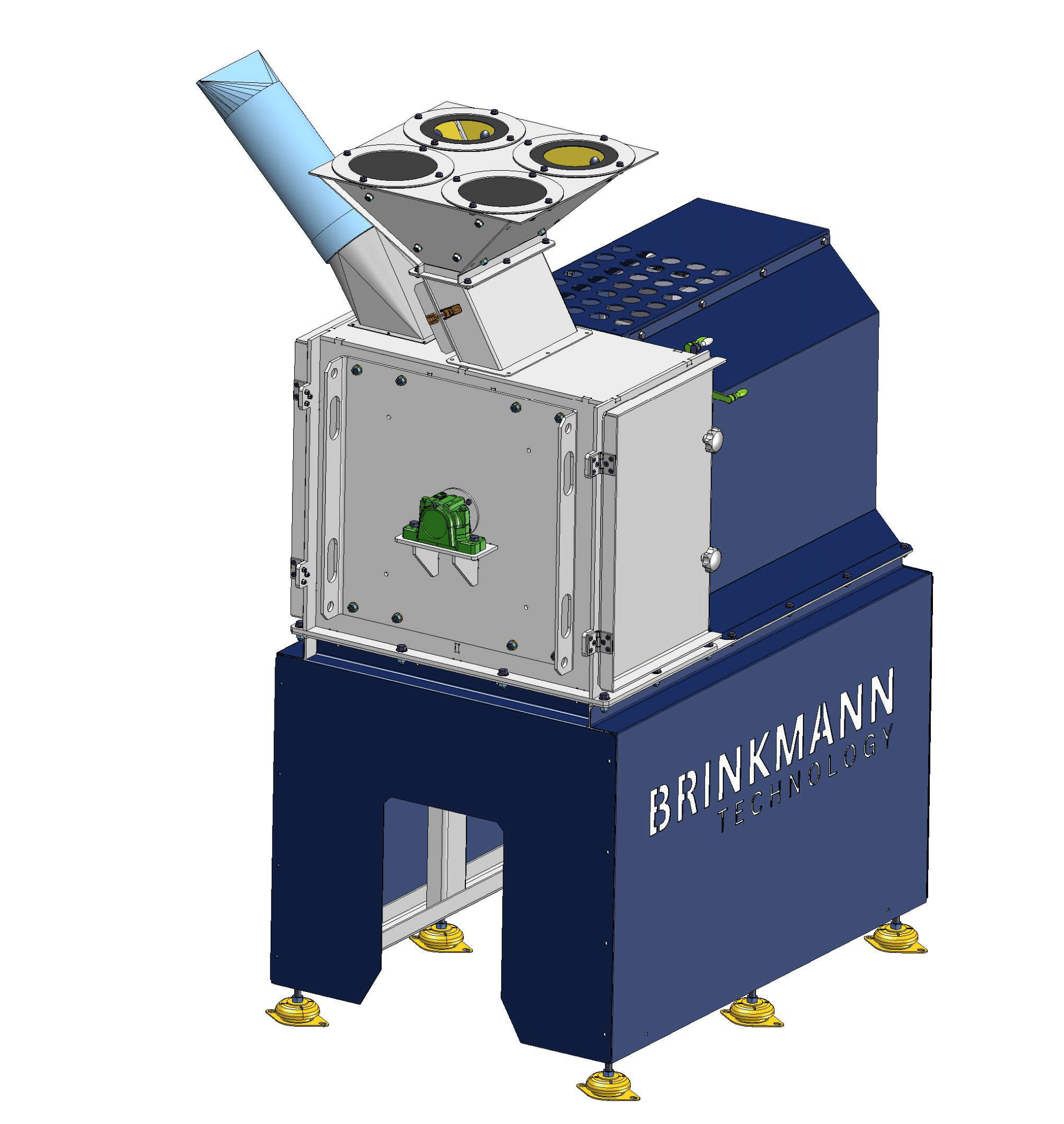

Components

The main components

of the Grinding and Mixing Plant

Mill

Our Milling Technology

Blowerless mill for grain with 24-192 carbide hammers per model

High drive power of up to 220 kW with blowerless mill

Powerful grinding capacity of 2000 - 44,000 kg/h thanks to the high-quality grinding technology of the hammer mill

Very long service life

Mixer

Our Mixing Technology

Feed Mixer

- Capacity from 1,000 to 3,000 kg

- Mixing time depending on model approx. 5 - 10 min

- Motor power depending on model approx. 4 - 7.5 kW

Our feed mixers meet

the following requirements:

Height depending on model 2.1 - 5.1 m

Mixing accuracy 1:100.000

Up to 5 % oil addition

Residue-free emptying & multiple outlets possible

Electronic weighing

Industrial Mixer

- Capacity from 1,000 to 7,000 kg

- Mixing time depending on model approx. 5 - 10 min

- Motor power depending on model approx. 7.5 - 18.5 kW

Our industrial mixers meet

the following requirements:

Height depending on model 4.6 - 6 m

Mixing accuracy 1:100.000

Motor with 1.000 rpm

Up to 5% oil addition

Several outlets possible

Dust-free dosing

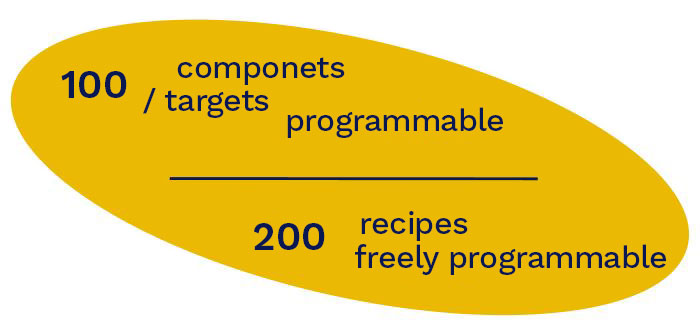

Control

Our Control technology

Automation of the grinding and mixing operation

Complete control cabinet incl. control system

External start (e.g. via empty indicator) and external stop (e.g. via full indicator); continuous level measurement

Operating hours counter & fuse monitoring